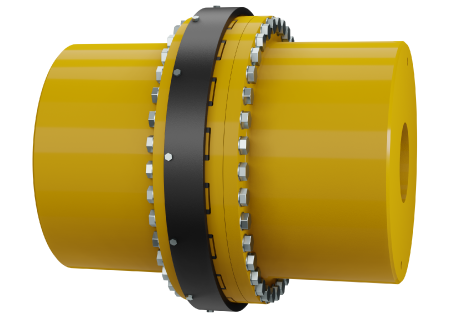

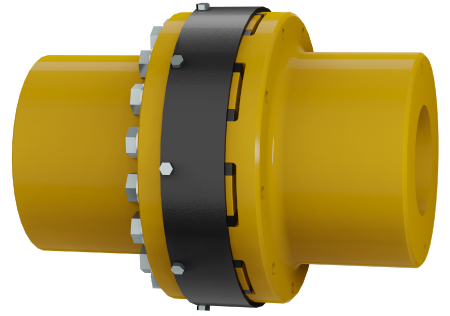

The ZETA line features elastic claw couplings, designed to withstand very high torques without, however, compromising their efficiency. Furthermore, its compact construction and low weight make installation easy. This provides economy and agility, serving torque transmissions in heavy and extra-heavy duty, from 200,000 Nm to 1,785,000 Nm.

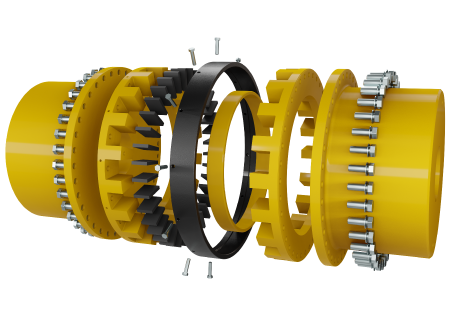

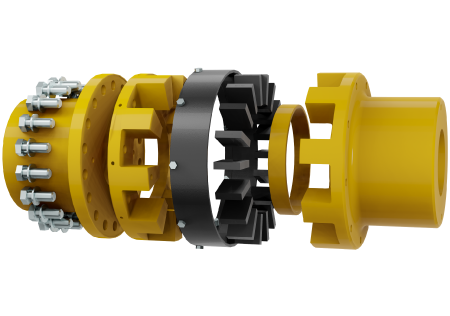

One of the main differences that the line offers is the possibility of replacing elastic couplings with cylindrical claws interchangeably. Consequently, this will allow a greater relationship between transmitted power and moment of inertia (J).

The ANTARES ZETA line is the ideal solution for applications such as long-distance belt conveyors, overhead cranes and mills. Furthermore, it is effective in segments such as Mining, Steel, Cement, Sugar and Alcohol and Ports.

ANTARES ZETA Couplings not only transmit torque and power, but also improve transmission efficiency and effectiveness. They reduce energy consumption and carry large loads with a lower mass, thus resulting in a higher ratio between transmitted power and GD2 moment of inertia.

Furthermore, the fatigue limits of ZETA’s metal components meet the most demanding applications on the market.

Another point to highlight is that the development of high-performance elastomers was carried out through rigidity tests in the laboratory and full-size bench tests.

Finally, the screwed union of the ANTARES ZETA Coupling has the capacity to transmit torque through friction, thus guaranteeing safe application in large variations in inertia of mechanical systems.