The AGD line of gear couplings is manufactured with triple-crowned teeth. This technology results in superior lifespan, as the stress during transmission is shifted to the center of the teeth.

Accommodates radial and angular misalignments, protecting equipment. These couplings are manufactured in accordance with the AGMA 9008 B00 standard (revision of 516.01), being interchangeable with couplings that follow this standard.

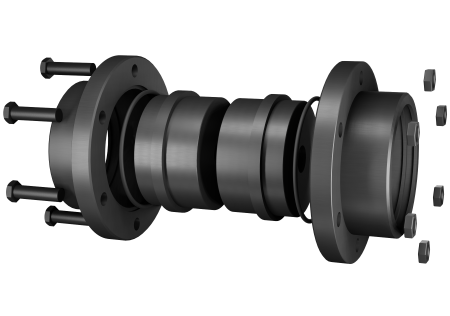

Configurations

They are manufactured with triple-bulged teeth. This technology results in a longer service life since, during transmission, the tension is moved to the center of the teeth.

They can be manufactured with double engagement (AGD), single engagement (AGS), or two rigid hubs (RG). Consult for other special versions.

Lubrication

Proper lubrication is essential to maximize the lifespan of your transmission. It is recommended that the lubrication interval does not exceed 6 months. Use grease for lubrication, injecting it into the hole in one of the toothed covers until excess overflows into the other hole. Afterwards, insert the plugs into the toothed covers.