How to install your coupling

The correct assembly and installation of the couplings are essential for their good performance and for the ideal functioning of the equipment where they are installed. It all starts with the right choice. Have the power, speed and shaft diameters of the application at hand. On our website, you can easily do the sizing. And remember that some applications require more specific templates.

How to disassemble and assemble couplings?

We have a video where you can see the Assembly and Installation demonstration. Access here.

Montagem dos Acoplamentos

Now, let’s go step by step, first, the assembly.

1) Mount the previously machined hubs on the shafts. Check which shaft/hole fit indication is for the application in question. Afterwards, use the most suitable method for assembly (heating, hydraulics…);

2) Align the drive and application shafts as indicated by the equipment manufacturer;

3) Check the axial distances and assembly tolerances according to the used coupling model. Always use the coupling manufacturer’s assembly manual for assistance during assembly;

4) An important tip is that several coupling models – such as the tire – require some care when tightening the screws. This is indicated in the manufacturer’s catalogue, but if in doubt, use a torquemeter.

Disassembly of Couplings

To disassemble the couplings, use tools that do not damage their components. Couplings that use fastening elements or shrink disks allow easy disassembly, without the need for hydraulic or pneumatic devices.

Take out the components and check the spares for wear. Always have wear items in stock, this avoids unexpected stops, speeds up maintenance and reduces machine downtime.

Quais Cuidados Tomar Durante a Montagem de Acoplamentos?

After understanding how to assemble couplings, we still need to reinforce some simple precautions that make all the difference.

Check out what they are:

- Never carry out the assembly of the cubes by means of blows

- Make sure that the equipment is well locked

- See if lubrication is necessary

- Also follow the manufacturer’s instructions.

What Are Couplings?

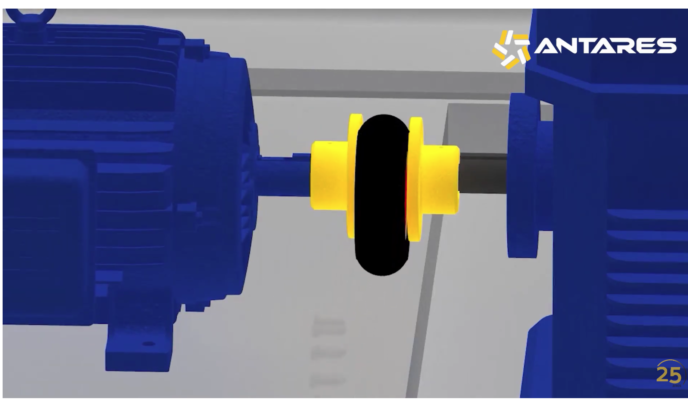

In industry, there are several machines that work through rotary movement. For this to happen, with the engine and machine aligned, couplings are essential.

But why anyway?

These mechanical components are responsible for uniting two pieces of equipment from different systems and, in this way, transmitting the drive power to the application.

Analogously, a classic case of this is the combination between a pump and an engine, for example.

What Are Industrial Couplings For?

Equipment care is absolutely important. This is because couplings not only serve to unite the drive to the application, but also to avoid various risk situations, including:

- Exce

- ssive mechanical vibration

- Equipment failures

- Wear beyond normal

- Reduction of the useful life of machines and their components

- Overtorque

- Among others.

It is for these and other reasons that understanding more and more about couplings brings many advantages to your work and performance.

What are the Main Types and Characteristics of Couplings?

Since you know everything about defining, concept, disassembling and assembling business-friendly couplings, let’s see what types are available? It is possible to find rigid, flexible and elastic couplings. So, check out the differences between them:

Rigid Couplings

Unite the axes as if they were just one.

Flexible Couplings

In principle, these models accommodate misalignments and reduce vibration. They can be flexible in only one or more directions. For example: tire coupling (this also absorbs shocks), gear, elastic grid, among others.

Elastic Couplings

As the name implies, they have an elastic structure that offers greater flexibility to adjust twists and displacements.

Like the tire coupling, they accommodate misalignments, reduce vibration and absorb shock.

What are the Main Causes for Breaking a Coupling?

In addition to mounting and dismounting couplings, it is also worth knowing the main reasons for failures.

Therefore, we separate three very common situations that can be avoided easily. Look:

Lack of Lubrication

The lack of lubrication sometimes leads to failures and accelerated wear problems in components that suffer friction during coupling operation. Therefore, it is always worth checking the manufacturer’s instructions and taking care not only during installation, but periodically. It is often interesting to opt for a dry coupling – that is, without lubrication.

Misalignment between Shafts

Another factor that leads to a coupling breaking is the lack of shaft alignment and the use of a suitable coupling for each situation.

We know that it is often not possible to carry out a proper alignment, either due to lack of alignment devices, difficult access to perform the alignment or even the short time to put the equipment into operation, preventing the plant or the production line from remaining stop.

But a good time to perform the alignment is during a shutdown, even with insufficient tools.

Remember: poor alignment is better than no alignment.

Overload

Since overloads are common in production processes, within normal limits, they do not affect the drive components, however, in extreme cases, they can damage shafts, bearings, bearings and the drive itself (motor/gearbox). In some cases, the couplings act as fuses, breaking to protect the motor and reducer from overload.

To avoid any kind of problems, here is an essential tip: industrial maintenance.

This process consists of inspecting parts, equipment, machines and evaluating production. The more you know of the industry standard, the better, accordingly.

After all, the idea is to identify performance deviations and act before any major problem appears, in other words.

In short, it is also valid to have a history of each machine and train all teams correctly.

Conclusion

In summary, couplings are key parts for industrial production, no matter what segment it is from. This is because the couplings ensure the transmission of torque between drive and application, in addition to accommodating misalignments, reducing vibration and dampening shocks and torque peaks from the process, of course.

All this without failures, excessive vibration, overload and other dilemmas, in short.

But, it’s always worth remembering… For everything to work perfectly, correct assembly and disassembly is necessary, as we demonstrate in this article.

Another point is that couplings need to be inspected whenever possible. In summary, this is the only way to foresee problems and act as soon as possible.

So, take advantage now that you already know more about the subject in question and look for much better results!

After all, all the tips we share here can help you increase the number of productions, quality and, of course, customer satisfaction.

Suzana Facilito relacionamentos através das ações e ferramentas construídas a partir do marketing estratégico e digital.