Floating Shaft for Vibrating Screens

Vibrating screens are responsible for separating heterogeneous mixtures through the vibration of perforated metal grids or sheets while the material passes through the equipment. Screens work through vibration exciters that exert an oscillatory force that shakes the perforated metal grids or sheets.

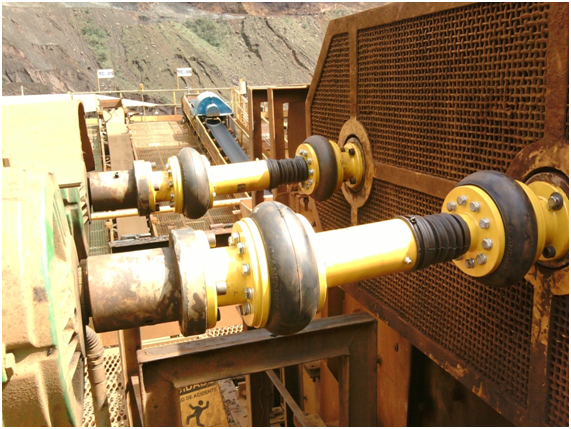

In this fact sheet, we will focus on vibration exciters that use eccentric cams, typically activated by a cardan shaft, as shown in the photos. This torque transmission give independence to the system driving is used forces, to with two universal joints, a shaft and a splined sleeve.

The vibration is excited through eccentric cams or vibrating modules under the screen structure, driven by an electric motor. In short, the motor is fixed to a base and the cardan shaft connects the motor which moves radially, to the supported screen by shaft, springs, generating the vibration necessary for the screen to function.

With the motor fixed and the radial displacement of the screen, the cardan shaft must have a spline to allow the axial movement of the assembly. Consequently, this makes it possible to compensate for the change in length according to the amplitude of the vibration. Additionally, the greater the vibration amplitude, the greater the shaft length variation.

Moreover, the use of cardan shafts in this application entails constant maintenance and, as a result, requires cardan recovery work in specialized companies. Therefore, this leads to high maintenance costs and sieve downtime.

Cardan shafts characteristics:

- require periodic lubrication;

- do not absorb shocks or vibrations (they are torsionally rigid);

- maintenance carried out only by specialized companies;

- more difficult inspection, as it is necessary to disassemble the set;

- high maintenance cost (parts, manpower, transportation to the maintenance location, etc.).

Presenting the Antares Solution: Floating Shaft for Vibrating Screens

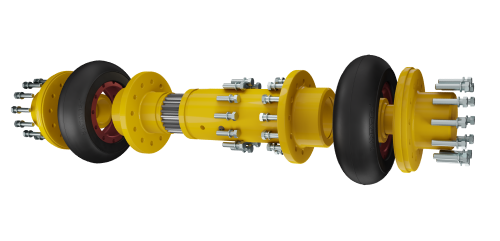

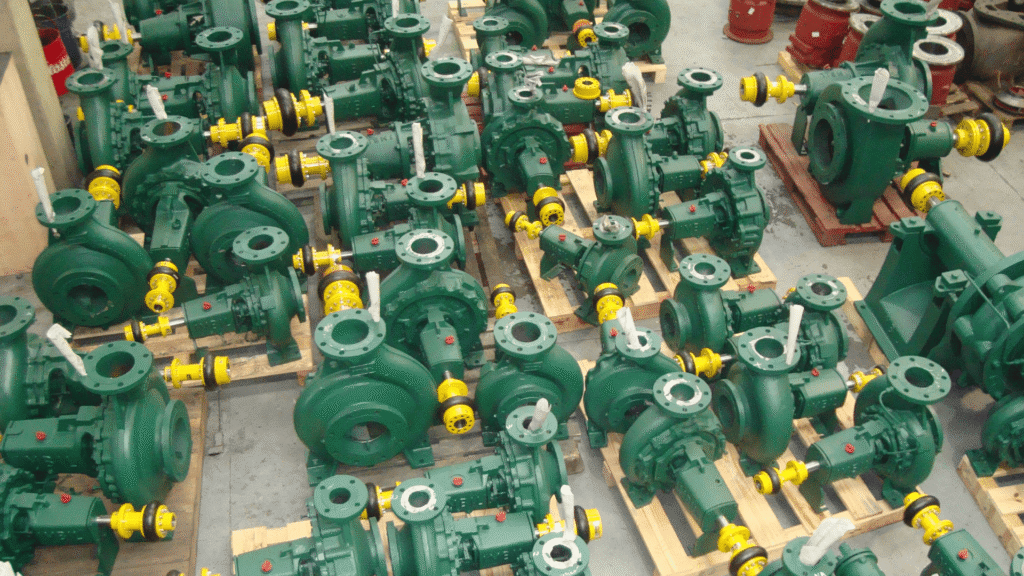

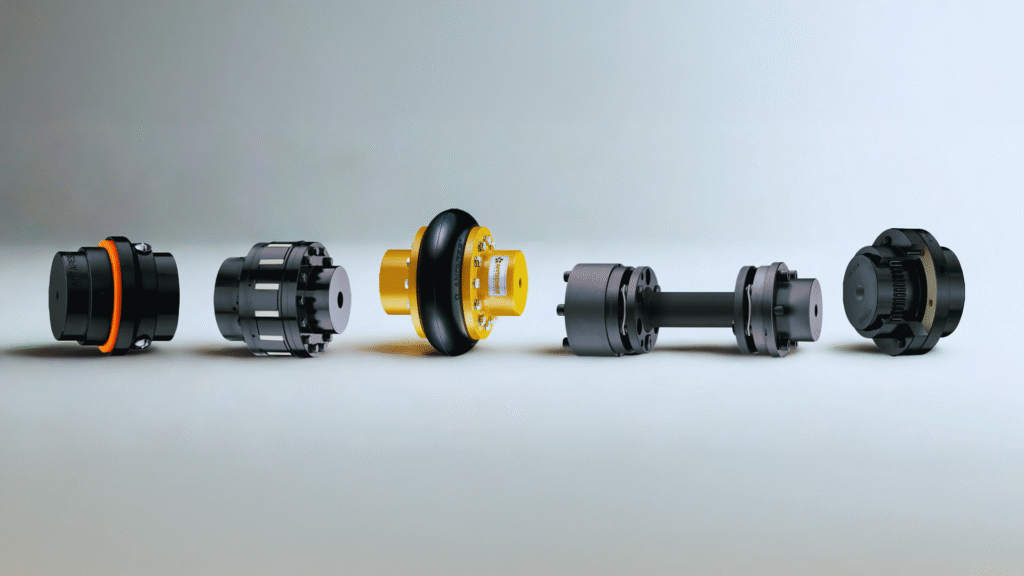

As a result, ANTARES developed a solution for this application: the AT-EF FLOATING SHAFT COUPLING. The floating shaft brings the advantages of the AT couplings, such misalignment and absorption capacity.

Floating shafts are made of two elastic centers from the AT line and other components such as ball joints, splined shafts and hubs. The elastic center provide the ability to accommodate misalignment, and absorb shocks, blows and vibrations. And the spline on the floating shaft compensates for variation in lenght during operantion.

Due to the flexible characteristics of the elastic center, this sealing model deliver a very impressive result in replacing cardans, mainly for use in vibrating screens in all sectors.

AT-EF couplings can interchangeable flanges, be so that supplied the with customer simply removes the central cardan assembly and replaces it with our coupling, keeping the original cardan hubs/flange.

Another option is to completely exchange the cardan assembly for the AT-EF using the hubs supplied by Antares.

Maintenance is very simple, carried out by visually checking for damage and damage to the elastic center. You can carry it out during plant stops (without dismantling the coupling). You can also carry it out while the coupling is operating, using a strobe light.

AT-EF COUPLING CHARACTERISTICS

- Does not require lubrication.

- Great absorption of shocks and vibrations.

- Simple maintenance carried out by the user.

- Easy visual inspection without the need to disassemble the assembly.

- You can carry out the inspection with a strobe light, without needing to stop the equipment.

- Low maintenance cost and availability of spare parts.

To initially select the correct size of the AT-EF Coupling we need the following information:

- Engine power and rotation.

- DBSE = Distance Between Shaft Ends.

- Cardan flanges dimensions (if customer prefers to keep them), or the diameter of the motor shafts and sieve for use with Antares cubes.

- Total amplitude of displacement during the vibration process.

Suzana Facilito relacionamentos através das ações e ferramentas construídas a partir do marketing estratégico e digital.