Couplings: types, applications, and choosing the ideal model

Couplings are essential components for torque transmission between shafts in rotating systems. They are found in virtually every industrial plant — from mining operations to sugar-energy mills — and play a key role in equipment protection, performance, and service life.

Despite their wide application, many professionals still have important questions about the topic:

- What are couplings and what is their main function?

- What types of couplings are available and how are they applied?

- How do you properly size an industrial coupling?

- What should be considered when specifying or replacing this component?

In this article, we have gathered technical information and practical guidance to support engineers, buyers, and maintenance teams in selecting and properly using couplings.

Couplings: what they are and what they’re used for

Couplings are mechanical elements used to connect two rotating shafts, enabling torque and rotation transmission between them. Their main function is to ensure motion continuity even in the presence of angular, parallel, or axial misalignments between shafts. They absorb shocks and vibrations generated during operation.

In practice, couplings are used between the driver (such as electric motors, combustion engines, or turbines) and the driven equipment (like pumps, belt conveyors, gearboxes, or fans). They are present in any rotating system and are essential to protect machine components and extend the mechanical assembly’s service life.

In addition to transmitting power, industrial couplings help compensate for alignment imperfections, reduce dynamic loads on bearings, and prevent damage caused by sudden starts, load peaks, or unexpected failures. Choosing the right model can significantly reduce component wear and increase equipment uptime.

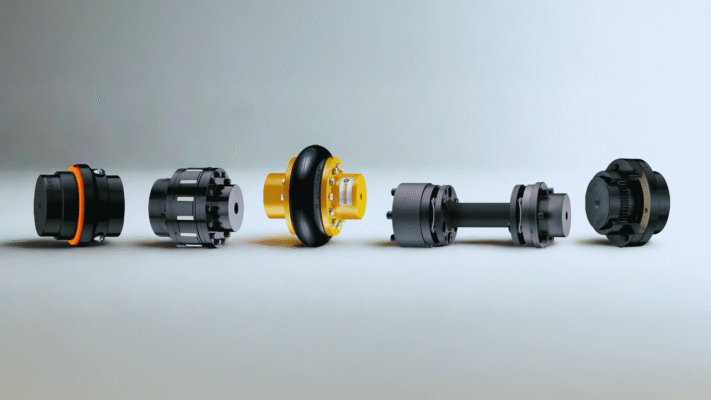

What are the main types of mechanical couplings?

Mechanical couplings fall into several categories based on their design and function.

Each type is engineered to meet specific needs, such as misalignment compensation, shock absorption, high-temperature operation, or high torque transmission. Choosing the right model depends directly on the system’s operating conditions.

Below are the main types of couplings used in the industry.

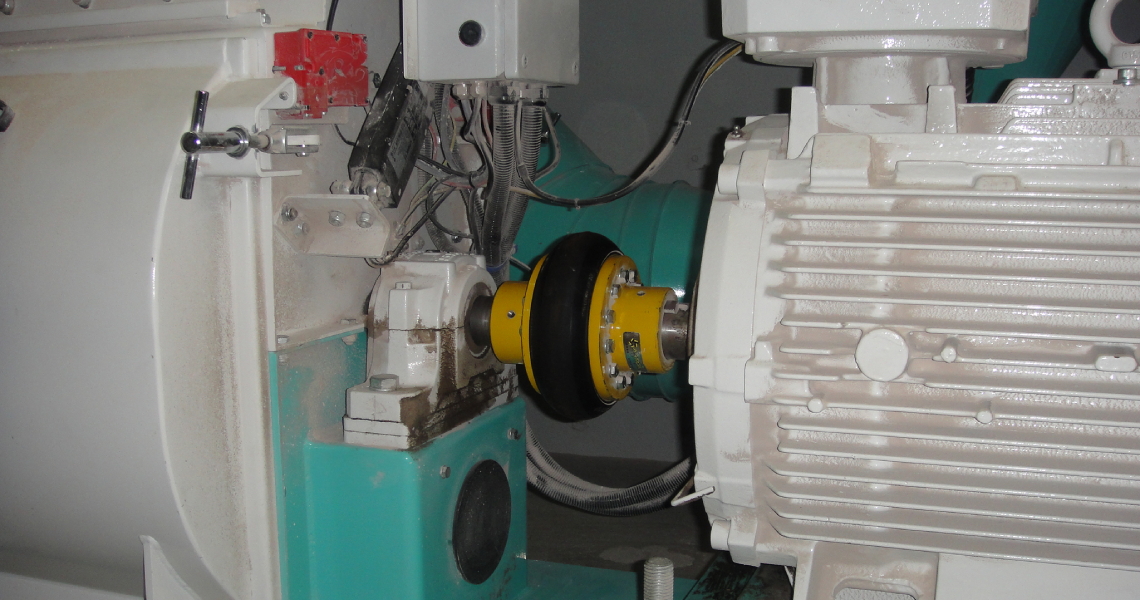

Antares AT flexible coupling installed on a hammer mill drive system in the agribusiness sector, connecting the electric motor to the gearbox.

Flexible couplings

Flexible couplings are the most common in industrial applications. Their key feature is their ability to compensate for misalignments between shafts — responsible for roughly 50% of bearing failures. That’s because machine elements like seals, retainers, and gears are not designed to withstand bending-induced shaft stress.

Main advantages of flexible couplings:

- No lubrication required, especially in models with polymer-based elastic elements.

- Maintenance-friendly, particularly in split versions with divided elastic centers, ideal for tight shaft-end spaces.

- Noise and vibration damping, due to mechanical isolation between driver and driven equipment, helping create safer, quieter industrial environments.

Antares HR elastic coupling installed on a rubber conveyor system in the sugar and ethanol industry, enabling power transmission between the gearbox and drive shaft.

Elastic couplings

Elastic couplings also handle misalignments and perform well in vibration damping. Most modern models allow visual inspection of internal components without disassembly, reducing downtime.

Benefits include:

- Lubrication-free operation, lowering maintenance cost and complexity.

- Inspection convenience, with visible elastic elements even when installed.

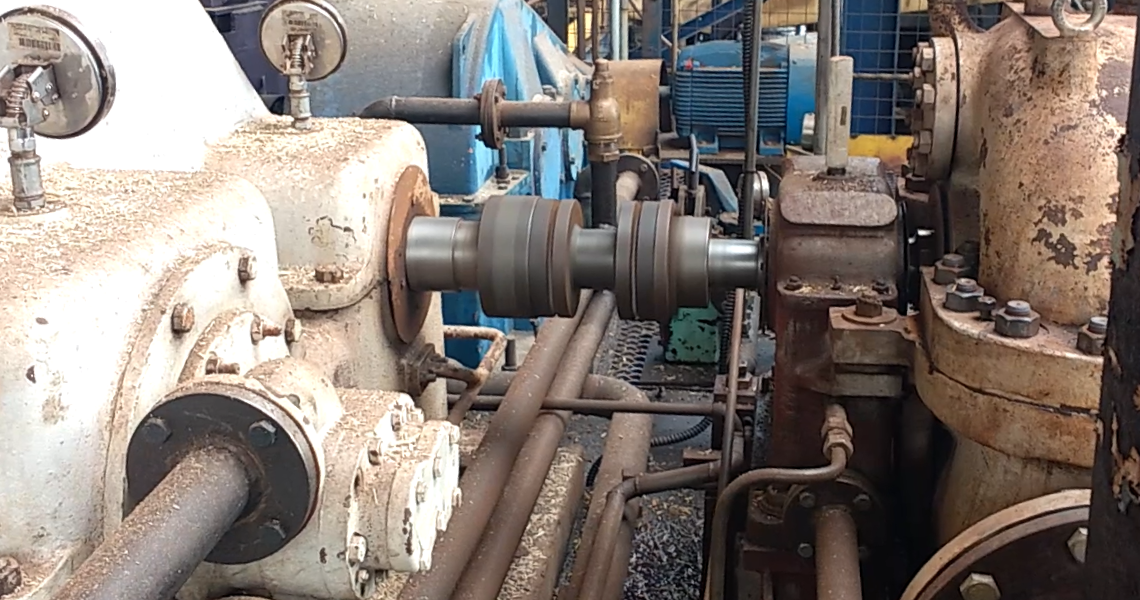

Antares RSK disc coupling operating in a sugar and ethanol industry system, connecting high-torque rotating equipment in a critical transmission line.

Disc couplings

Disc couplings consist of precision-machined metallic discs. They withstand high temperatures and allow high-speed rotation with accurate balancing. Their torsionally rigid but flexible structure accommodates axial, parallel, and angular misalignments.

Key features of disc couplings:

- Wear-free and lubrication-free.

- Quick disc replacement, without moving the connected equipment.

- High thermal resistance, suitable for demanding applications.

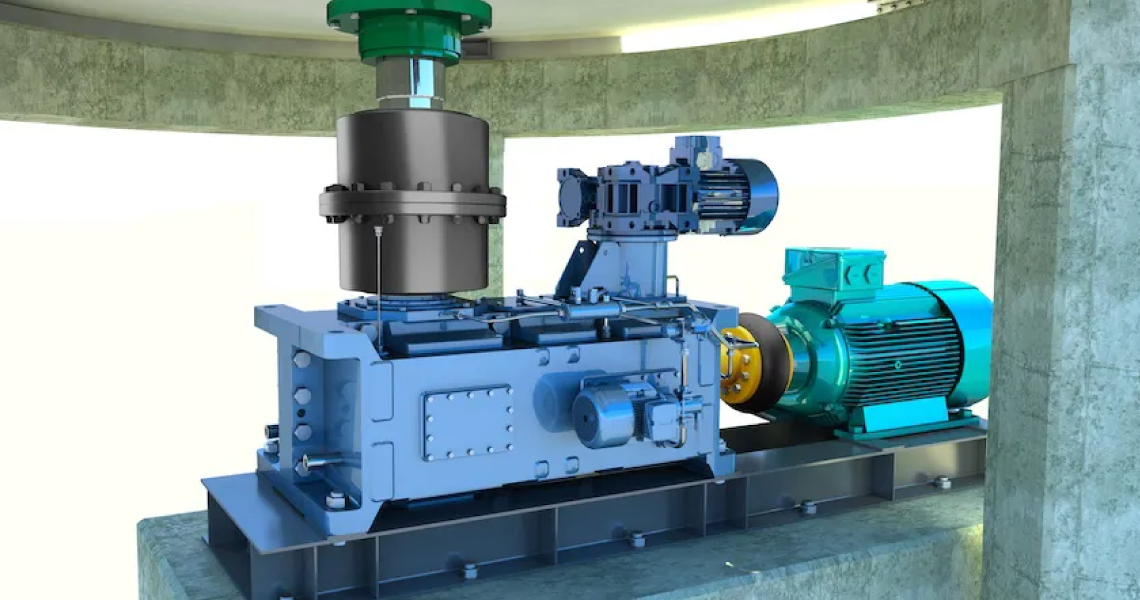

3D rendering of an Antares AGS V HD gear coupling installed on the top shaft of a soybean desolventizer.

Gear couplings

Designed for high torque transmission, gear couplings have crowned teeth that distribute stress more evenly during operation. They are extremely robust and ideal for heavy-duty applications such as gearboxes, mills, and large rotating equipment.

Key characteristics:

- Require periodic lubrication to ensure durability and proper function.

- Compact assembly, with a high torque-to-size ratio.

- Usable with floating shafts, due to high torsional rigidity.

What are couplings made of and where are they used?

The construction of a coupling depends on its type and application, but typically includes two hubs mounted on each shaft end and a central element — which may be elastic, metallic, or toothed. This structure enables torque transmission while accommodating misalignments and absorbing mechanical shocks.

In gear couplings, for example, the elastic element is replaced by a lubricated tooth assembly designed to transfer high torque levels accurately. In flexible or elastic models, the center consists of materials that allow torsional flexibility and vibration isolation.

Where are couplings used?

Virtually all industrial sectors rely on couplings to ensure reliable operation of rotating machinery. This ranges from light-duty applications like fans and centrifugal pumps to heavy equipment in continuous and critical operations.

Key industries using industrial couplings include:

- Mining

- Steel and metallurgy

- Food processing

- Petrochemical

- Sugar-energy sector

- Agribusiness and grain processing

Couplings’ versatility allows them to be used at various stages of the production process, from main drives to auxiliary systems. Thus, proper model specification is critical to avoid mechanical failures and reduce long-term maintenance costs.

The evolution of couplings in the industrial sector

Couplings have undergone significant transformations in recent decades, keeping pace with industrial process modernization and increasing demands for performance, reliability, and efficiency.

Initially, couplings were rudimentary — based on rigid joints and universal joints with little or no misalignment tolerance. Until the early 20th century, the dominant design was the rigid coupling, which required precise shaft alignment and offered no overload or vibration protection.

With advances in precision machining, stronger materials, and the development of elastic elements, new types of couplings emerged: lighter, more durable, and more adaptable. Metallic disc models began to serve high-speed, high-temperature systems, while flexible types gained popularity for ease of maintenance and excellent vibration absorption.

Today, couplings incorporate technologies such as:

- Engineering software for custom sizing.

- Materials with greater elasticity and wear resistance.

- Optimized geometries to reduce noise and improve dynamic balance.

The current demand for more compact components with higher torque density and low maintenance continues to drive coupling evolution. The goal remains the same: ensure system reliability even under extreme operational demands.

Why coupling selection is critical to equipment performance

Although they represent a small portion of a production line’s overall investment, couplings directly affect the performance and reliability of rotating machinery. A properly specified model reduces the risk of mechanical failures, increases component life, and contributes to equipment availability.

Key benefits of choosing the right coupling include:

- Greater system reliability: prevents failures due to misalignments and mechanical shocks.

- Reduced unplanned downtime: fewer corrective interventions, better process continuity.

- Preservation of bearings and seals: misalignment is a leading cause of failures in these parts.

- Lower operational costs: less maintenance and fewer replacement parts.

Contrary to what it may seem, replacing a coupling with a generic or unsuitable model can compromise the entire system. Incorrectly specified couplings can cause overloads, excessive vibration, premature component wear, and even shaft breakage.

Therefore, beyond the unit cost, it’s essential to evaluate performance, equipment compatibility, and technical support from the manufacturer. A well-sized coupling is an investment in plant uptime and operational safety.

What to consider when purchasing a coupling

Coupling selection involves more than matching dimensions or price. To ensure performance and durability in industrial environments, it’s crucial to analyze application conditions and rely on qualified technical support during specification.

Here are three key factors to consider:

1. Machine operating conditions

Before selecting a model, fully understand the environment and application demands. Assess:

- Required torque and transmitted power.

- Type and degree of shaft misalignment.

- Existing vibration and damping needs.

- Shaft diameter, temperature, and working environment.

- Shaft-end distance and mounting constraints.

This data guides proper sizing and helps avoid failures due to undersizing or incompatibility.

2. Supplier’s technical support

An experienced engineering team can make all the difference. The manufacturer should provide:

- Assistance with sizing calculations.

- Recommendations based on real-world applications.

- Installation and maintenance support.

This reduces specification errors and provides greater safety for operations and maintenance teams.

3. Brand reliability and infrastructure

Choosing a manufacturer with a solid track record ensures:

- Spare part availability.

- Proven material quality and field performance.

- Ongoing technical support throughout the equipment’s lifecycle.

Many plants don’t have backup equipment. In such cases, selecting reliable couplings with fast delivery and local support is essential to productivity and operational predictability.

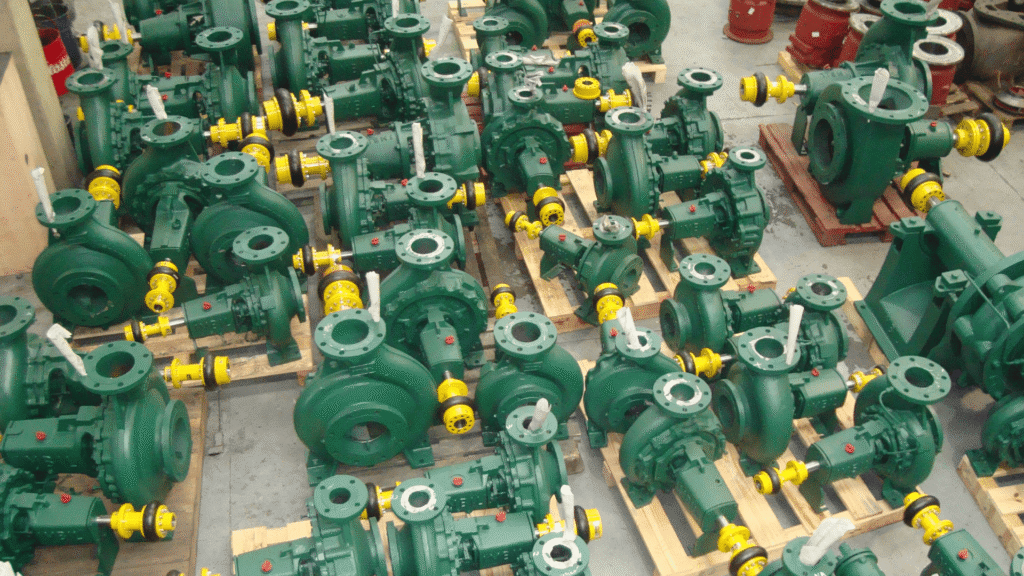

Antares flexible coupling installed on a slurry pump system, connecting a gearbox and motor in an industrial setting.

High-speed vs. low-speed couplings: what’s the difference?

In many industrial systems, the motor runs at a higher speed than the machine requires. To adjust this, gearboxes, pulleys, or belt-pulley systems are used. In this context, couplings are classified based on their position in the powertrain: high-speed (before the gearbox) or low-speed (after the gearbox).

High-speed coupling (gearbox input)

Installed between the motor shaft and the gearbox input shaft, this coupling runs at higher speeds and must absorb more aggressive misalignments and vibrations.

Common models:

- Highly elastic couplings, such as tire-type designs.

- Jaw couplings with flexible elastomers, engineered to minimize friction. between parts.

Using flexible, wear-resistant materials helps extend the system’s service life and protect other components.

Low-speed coupling (gearbox output)

Installed between the gearbox output shaft and the driven machine shaft, this coupling operates at lower speeds but transmits higher torque. Here, mechanical robustness is paramount.

Most common types:

- Gear couplings, due to their high torque capacity and torsional rigidity.

- Metallic jaw couplings, for compact installations requiring strong mechanical resistance.

In both cases, ensuring proper system balancing is essential to avoid bearing overload and preserve production performance.

Get the Full Coupling Catalog

Looking for the right solution to improve torque transmission, reduce maintenance, and increase equipment reliability? The Antares Coupling Product Catalog offers detailed technical information, product specifications, and application insights for a wide range of flexible, elastic, disc, and gear couplings used across the industrial sector.

Fillipe Rocha Fillipe Rocha é Analista de Marketing com mais de 11 anos de experiência em marketing B2B, inbound e conteúdo. É formado em Design Gráfico, especialista em Indústria 4.0 e já colaborou com Neil Patel, Texaco e outros.