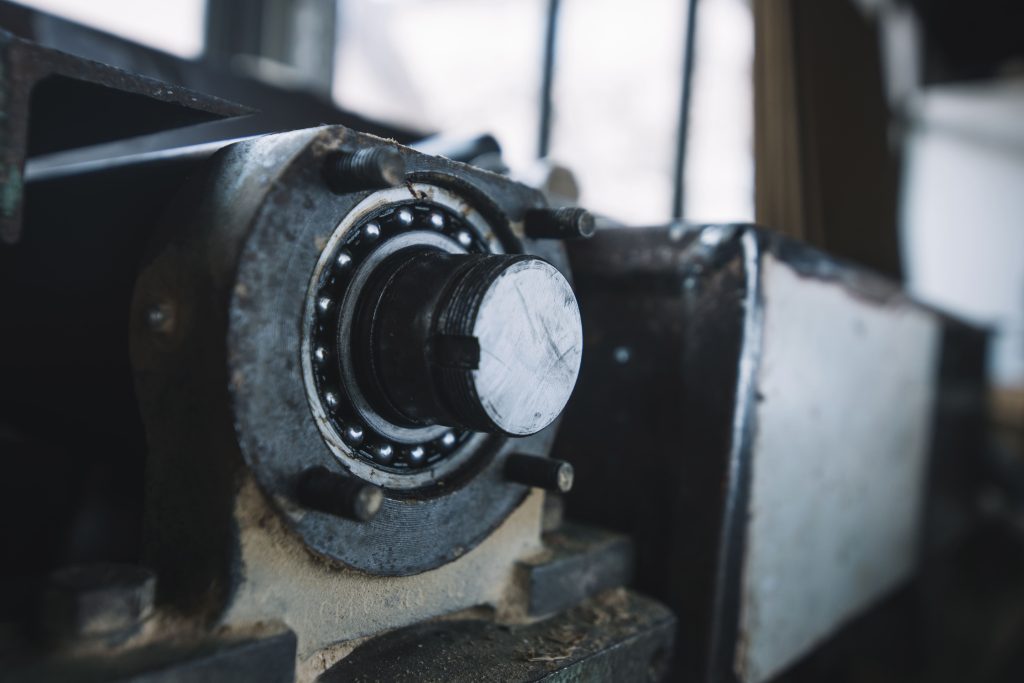

Upgrade your grid coupling.

Get a lubrication-free and easy replacement coupling that allows visual inspection, has higher misalignment tolerance and vibration damping capacity without gradual imbalance.

Even if your grid coupling is not breaking, it might be damaging your system.

Grease points

add failure modes and human errors

Tight alignment

pushes stress into bearings and seals

Hidden wear

becomes leaks, hot bearings, and rework

What you gain upgrading to AT Coupling Monobloc

No lubrication

Less downtime, more reliability.

High misalignment tolerance

Works with real-life conditions and not only perfect set-ups.

Greater vibration damping

Protects shafts, gears, seals, and bearings.

Change without moving.

The AT Monobloc coupling is designed so the elastomer can be replaced without moving the assembly.

Without gradual imbalance

The monobloc structure keeps the coupling balanced during operation.

Visual inspection

Check conditions quickly, even during operation with a stroboscope light.

Multiple applications

Replace a grid coupling with great advantages in most applications.

Yes, the more aligned the better.

But you don't need the drama.

Parallel misalignment tolerances

Yes, we know that the most the alignment, the better. However, with the AT line you spare the drama.

With misalignment tolerances up to 974% (parallel ) and 1640% (angular) greater than grid couplings, it’s much simpler to achieve (and maintain) the required shaft alignment without damaging the system.

Angular misalignment tolerances

AT Monobloc vs.

common U.S. couplings

| Points of Comparison |

Grid Coupling Grid Coupling

|

PU Tire Coupling PU Tire Coupling

|

Conventional Sectioned Tire Coupling Conventional Sectioned Tire Coupling

|

AT Coupling Monobloc AT Coupling Monobloc

|

|---|---|---|---|---|

| Needs Lubrication | Yes | No | No | No |

| Easy Maintenance | No | Yes | Yes | Yes |

| Maintenance Frequency | Very Frequent | Frequent | Frequent | Less Frequent |

| Visual Inspection | No | Yes | Yes | Yes |

| Capacity to absorb shocks | Null | Medium | Higher | Higher |

| Vibration Damping | Low | Medium | Higher | Higher |

| Misalignment Compensation | Low | Higher | Higher | Higher |

| Risk of accidents caused by the detachment of parts | Low | Higher | Higher | Low |

| Shelf Life | Long | Shorter | Long | Long |

| Balancing | Good | Good | Bad | Good |

| Points of Comparison |

Grid Coupling Grid Coupling

|

PU Tire Coupling PU Tire Coupling

|

Conventional Sectioned Tire Coupling Conventional Sectioned Tire Coupling

|

AT Coupling Monobloc AT Coupling Monobloc

|

|---|---|---|---|---|

| Needs Lubrication | Yes | No | No | No |

| Easy Maintenance | No | Yes | Yes | Yes |

| Maintenance Frequency | Very Frequent | Frequent | Frequent | Less Frequent |

| Visual Inspection | No | Yes | Yes | Yes |

| Capacity to absorb shocks | Null | Medium | Higher | Higher |

| Vibration Damping | Low | Medium | Higher | Higher |

| Misalignment Compensation | Low | Higher | Higher | Higher |

| Risk of accidents caused by the detachment of parts | Low | Higher | Higher | Low |

| Shelf Life | Long | Shorter | Long | Long |

| Balancing | Good | Good | Bad | Good |

Results you can expect by upgrading your systems to AT coupling

Longer MTBF on rotating assets.

Fewer seal leaks and bearing issues.

Easier maintenance and less rework during peak season.

Mess-free preventive maintenance

with no relube.

Standard parts across assets

(pumps, conveyors, fans).

Failure point elimination

strengthens your FMEA plan.

Frequently Asked Questions

Having 100% metallic structure, the grid coupling generates greater reactionary forces than the AT Monobloc Coupling. This means gear coupling transmits more vibrations and shocks to the system. Also, the greater spring coefficient, it stiffness increases with speed.

No. These models are better than grid couplings, but have lower torque capacity. Also, the AT Monobloc coupling does not generate gradual imbalancing, a chronic problem of traditional tire couplings.

After installation, the AT Monobloc coupling doesn’t require moving the equipment to change the coupling. It is a simple operation like changing a tire.

For extreme application, such as environments with acids, solvents or bases, we developed the ANTAC line, with a special formulations that will resiste these harsh environment conditions.

Yes. US-based local stock and quick response through phone (786) 866-2899.

6-month AT trial.

Zero-risk grid upgrade.

Upgrade one grid coupling for AT. If performance doesn’t improve within 6 months, we’ll refund you*. We handle sizing and onboarding with your distributor.

*Conditions apply.

Some of our clients

Choose your next step

Talk to engineering

Bring your RPM, power, shaft sizes, distance between shafts, environment, duty cycle. We’ll do the rest.

Share with your distributor

Get the one-pager, selection checklist,

and a ready-to-send email.

Request a quote

Get a custom quote for your specific application.

No commitment, just straight numbers and lead time info from our U.S. team.