Coupling types: what they are and how to use them correctly

Knowing the different coupling types available is essential to ensure the optimal performance of a mechanical drive system and to avoid premature failures. Couplings play a key role in various industrial settings by connecting shafts, absorbing misalignments, and ensuring continuous operation between machines.

In this article, we explain the main categories of industrial couplings, their applications, and the technical criteria you must consider when choosing one. Our goal is to give you a clear, practical view of how to select the best model for each operation.

Read on to see how the right choice can directly boost your equipment’s efficiency, durability, and productivity.

WHAT ARE COUPLINGS AND WHAT DO THEY DO

Couplings are mechanical components that join two rotating shafts to transmit torque and motion. This link can be rigid or flexible, depending on the system’s operating needs. Their main role is to transmit torque from the drive shaft to the driven shaft, even when there are misalignments or load changes. They also offer technical benefits that improve equipment life and performance.

Common functions of the various coupling types used in industry include:

- Compensating for shaft misalignments (axial, angular, and parallel).

- Damping shocks and mechanical vibrations.

- Protecting components such as gearboxes, motor-reducers, and bearings.

- Reducing vibration in the drive system.

MAIN COUPLING TYPES

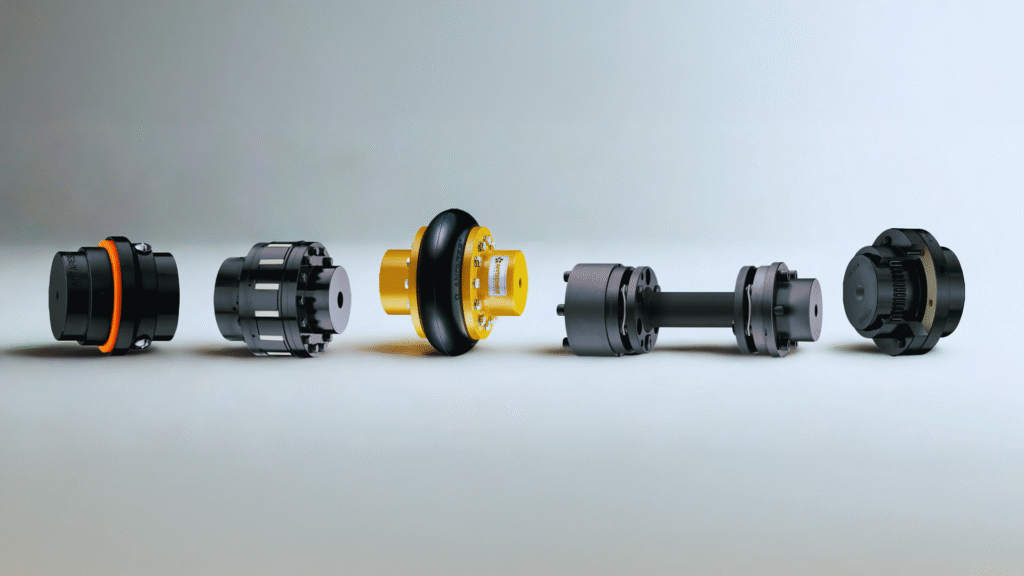

There are many mechanical coupling types, each designed for specific conditions. Your choice depends on torque level, misalignment, available space, and the type of machine. Below are the most common models, with links to detailed info:

- Flexible couplings

- Precision couplings

- Rigid couplings (fixed)

- Disc couplings

- Gear couplings

- Hydraulic couplings

- Magnetic couplings

Next, we detail each type’s main features and uses.

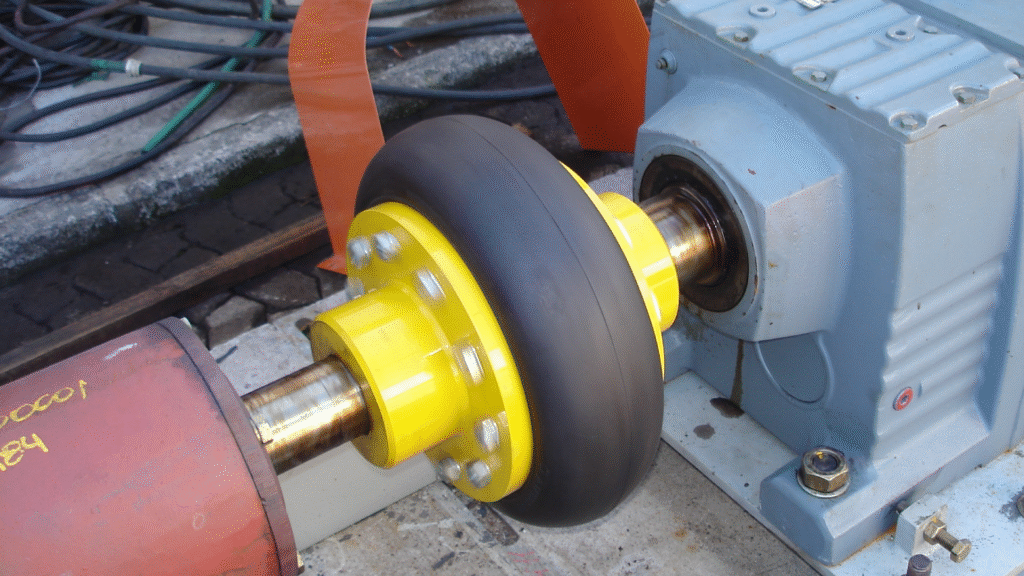

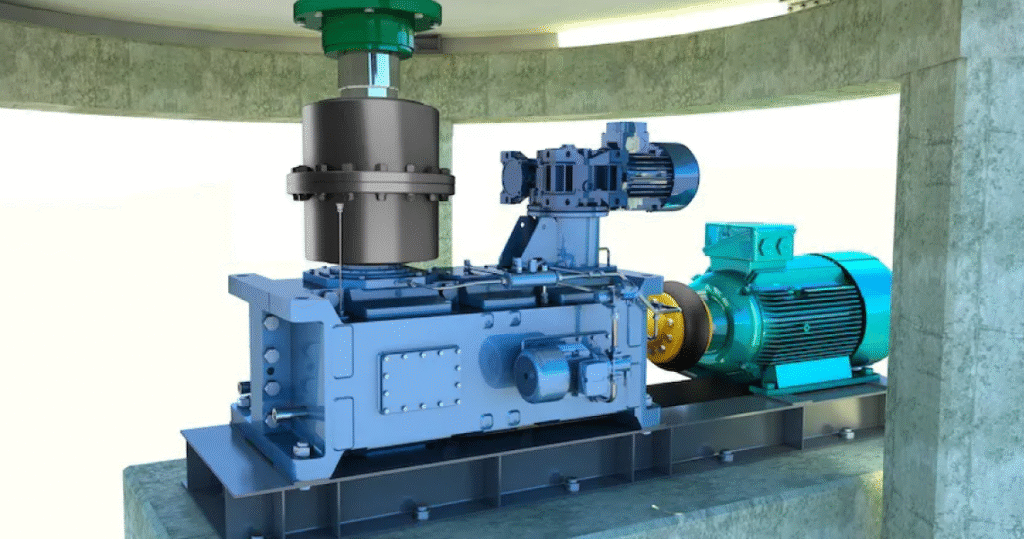

Antares AT flexible coupling connecting a drive shaft to a gearbox.

Flexible Couplings

Flexible couplings suit applications with shaft misalignment and where shock and load variation absorption is critical. Their design delivers smooth, safe torque transmission and protects system components.

They split into two groups:

- Elastomeric: transmit torque while damping vibration and load spikes—ideal for dynamic systems.

- Non-elastomeric: rigid but allow limited flex to handle moderate misalignment.

These models excel in versatility and extend the life of motors, gearboxes, and driven machines.

Precision Couplings

Precision couplings require exact alignment and zero backlash, ensuring sync between system parts. They handle high torque changes without motion instability. Use them in high-speed equipment, instrumentation, and automated systems.

Ideal for light-duty machines, position-control setups, and assemblies demanding low rotational inertia and fast response.

Rigid Couplings (Fixed)

Rigid couplings link perfectly aligned shafts without flex or vibration absorption. They deliver full torque directly. These robust units install easily and need little upkeep—perfect for stable systems.

Three main designs:

- Sleeve

- Flanged

- Two-piece

Choose based on space, torque, and mounting constraints.

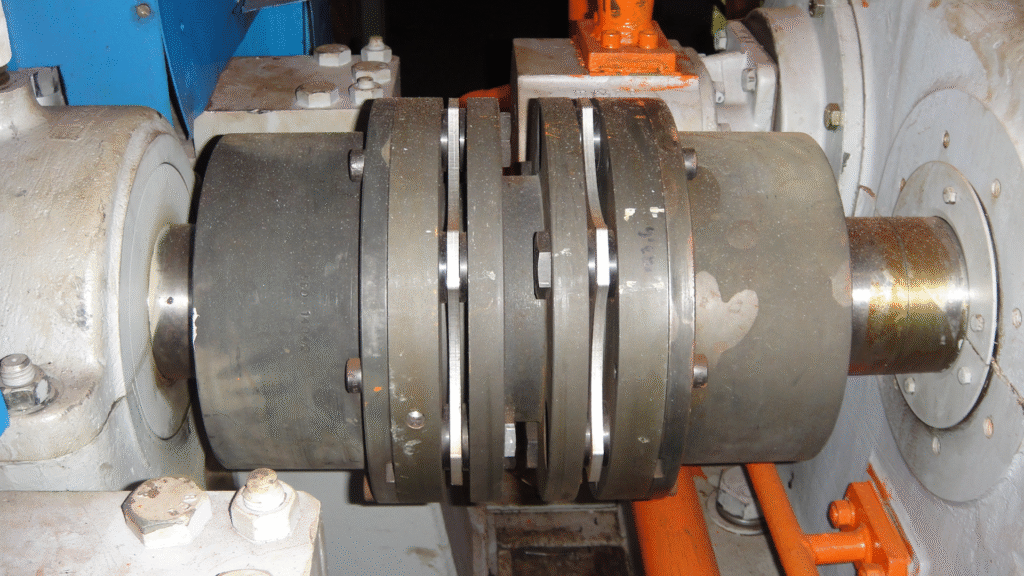

Metallic disc coupling connecting two rotating shafts.

Disc Couplings

Disc couplings, or diaphragm couplings, use thin metal discs to transmit torque with high precision while compensating axial, parallel, and angular misalignments. During operation, the discs flex to absorb relative shaft movements.

They require low maintenance, resist fatigue, and deliver minimal backlash—suitable for electric motors, compressors, and industrial pumps.

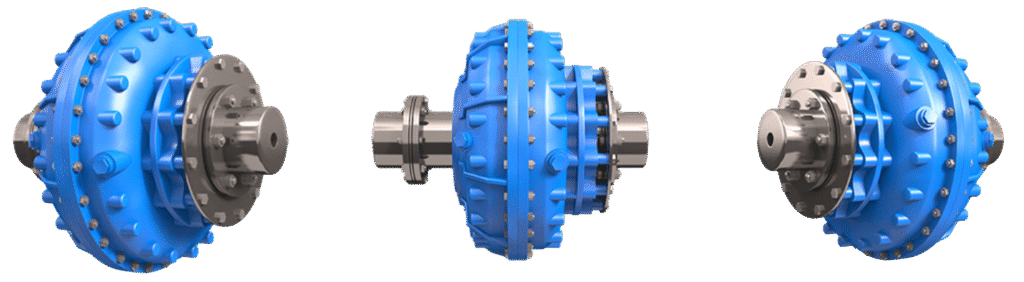

Gear Couplings

Gear couplings use toothed hubs and outer gears to handle high torque. They compensate misalignments in all directions—axial, parallel, and angular—while maintaining strong torque transfer.

Common in heavy-duty gearboxes, motor-reducers, mills, and rotary kilns.

Hydraulic Couplings

Hydraulic couplings transfer torque via fluid, without direct mechanical link. They consist of two impellers—one on each shaft—forming a pump-turbine system. The driving impeller moves fluid to drive the driven impeller.

This setup offers soft start, torque control, and overload protection. Use it on conveyors, industrial fans, and pumping systems.

Magnetic Couplings

Magnetic couplings transmit torque without physical contact, using a magnetic field between coupled rotors. They suit hermetically sealed, friction-free, wear-free applications. Use them in high-temperature or contamination-sensitive environments, such as sealed pumps, chemical plants, and pharmaceutical lines.

COUPLING CONSTRUCTION AND KEY APPLICATIONS

Most industrial couplings consist of two hubs (or flanges) linked by an intermediate element—elastomeric, metallic, or hydraulic—depending on the model. This assembly links a motor shaft to a driven shaft, ensuring efficient torque transfer in critical conditions.

Key Sectors Using Couplings

Couplings appear across all industrial sectors. The biggest demand comes from:

- Mining

- Agribusiness

- Metallurgy

- Food processing

- Steel industry

- Sugar-energy

- Petrochemicals

They drive equipment like:

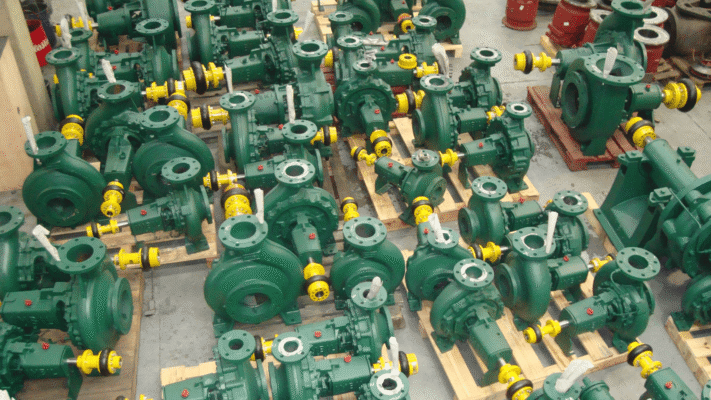

- Pumps

- Agitators

- Vibrating screens

- Conveyors

- Industrial elevators

- Compressors

- Fans

- Reactors

Proper coupling selection ensures operational reliability, cuts downtime, and boosts productivity.

WHY CHOOSING THE RIGHT COUPLING TYPES MATTERS

Selecting the right coupling affects your system’s efficiency, safety, and lifespan. A well-specified coupling enhances equipment performance and prevents repeated failures.

A high-quality coupling delivers:

- Vibration reduction and misalignment compensation.

- Longer life for motors, gearboxes, and bearings.

- Higher productivity and fewer unplanned stops.

- Simpler preventive and corrective maintenance.

Investing in the right coupling is not just about cost—it’s a strategic choice to protect assets and secure operational reliability.

CRITERIA FOR CHOOSING THE RIGHT COUPLING TYPES

To pick the ideal industrial coupling, assess these factors below.

1. Equipment Operating Conditions

Each machine has traits that guide coupling choice. Evaluate:

- Vibration type and intensity

- Potential misalignments (axial, parallel, angular)

- Power and torque requirements

- Operating environment (temperature, humidity, chemicals)

The wrong coupling raises maintenance costs and hurts performance.

2. Manufacturer Technical Support

A good supplier offers more than products. It provides engineering support for sizing and selection.

Antares has specialized engineers who help you choose the best coupling for your needs. Their expertise cuts operational risks and boosts your confidence in the selection.

3. Supplier Reliability and Track Record

Choose established brands to ensure:

- Quality materials and processes

- Compliance with technical standards

- Custom solution support

- After-sales service

At Antares, we blend industrial heritage and innovation, delivering couplings for key sectors with top performance and reliability.

RISKS OF USING THE WRONG COUPLING TYPES

A mismatched coupling poses real risks:

- Shorter life for bearings, shafts, and gearboxes.

- Longer corrective maintenance stops.

- Unexpected failures and premature breaks.

- Wasted energy and higher input costs.

- Structural damage from excess vibration or misalignment.

Consider total operating cost, not just purchase price. A proper coupling avoids rework, boosts system reliability, and cuts expense over time.

For high-performance couplings, explore Antares, Brazil’s reference in torque transmission and applied engineering.

CONCLUSION

You’ve seen the main coupling types used in industry, their features, functions, and technical selection criteria. Each model meets specific needs for torque, alignment, vibration control, and operational robustness.

Choosing the right coupling is strategic: it ensures reliability, productivity, and asset protection. A knowledgeable supplier makes all the difference.

Antares delivers tailored solutions, expert support, sizing tools, and a full portfolio for any industrial need.

Contact our team to find the ideal coupling for your operation.

Fillipe Rocha Fillipe Rocha é Analista de Marketing com mais de 11 anos de experiência em marketing B2B, inbound e conteúdo. É formado em Design Gráfico, especialista em Indústria 4.0 e já colaborou com Neil Patel, Texaco e outros.