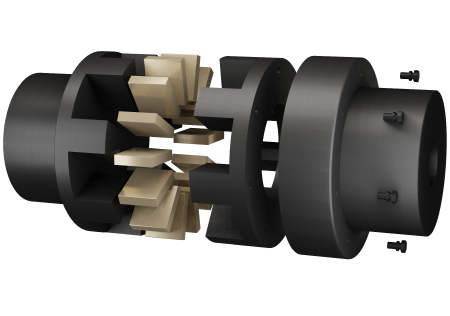

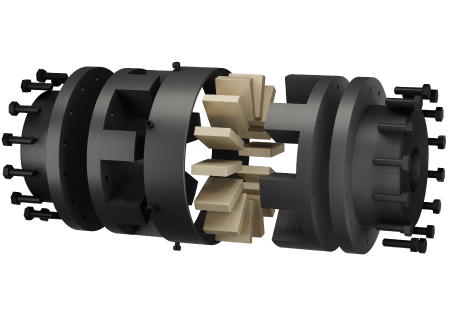

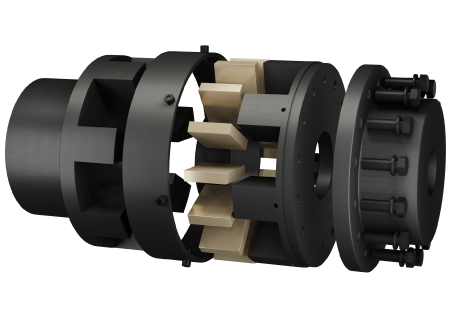

H/HR high torque elastic coupling is torsionally flexible, requires no lubrication and no need to move equipment to change elastic elements.

PRODUCT PROTOCOLATED WITH INPI – National Institute of Industrial Property.

High torque elastic coupling

The H/HR coupling line works primarily on high torque drives. This becomes clearer when we think about the torque range served by the coupling, which ranges from 12,000 Nm to 1,340,000 Nm and shafts up to 600 mm in diameter. Its use is most common in drives of bulk material transport equipment, for example, metal sugarcane conveyors, belt conveyors, sugarcane shredders, sugarcane choppers, elevators, primary mills and others.

Elastic elements

Generally, a coupling with an elastic polyurethane (PU) element is used at working speeds above 500 rpm, having greater torsional elasticity and greater capacity to absorb shocks and vibrations. This ensures that the machine components are protected from possible damage. The coupling with an elastic element in HTrans gives the coupling a significant increase in torque for the same size of the coupling, but with less capacity to dampen system shocks and vibrations. Furthermore, the ability to accommodate possible misalignments is not altered whether with a PU or HTrans element.