FEATURES

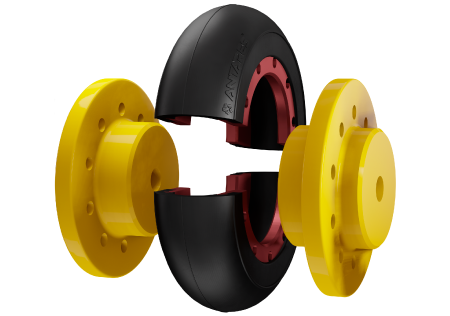

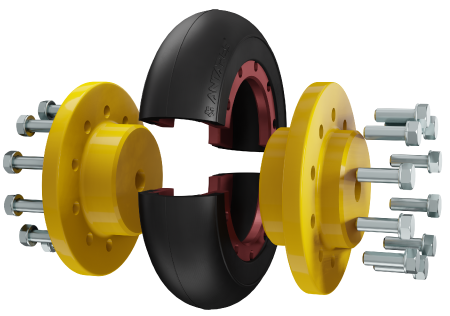

• Exclusive installation system in which tightening the screws guarantees the fixation of the elastic center

• Elastic element is fixed between hub and flange. Tightening the screws guarantees the resistance of the ELASTOMETER – METAL connection

• The screws are fixed in the axial direction, that is, they are not positioned in the direction of rotation. Therefore, they are also not subject to detachment due to centrifugal force, a common problem in other two-part couplings.

• Longer useful life, as the fixation of the elastomer with the metal is not subject to the action of aggressive environments or centrifugal force (acts in a direction perpendicular to the axis of rotation, moving material bodies away from it)

• Total safety, as the elastomer will not detach

• Greater torque capacity, making the product compact compared to other split couplings.